Turnover success for Sandwell metal manufacturer

Sandwell metal manufacturer Baylis Automotive has boosted its turnover to £5m after securing a number of new orders this year.

Sandwell metal manufacturer Baylis Automotive has boosted its turnover to £5m after securing a number of new orders this year.

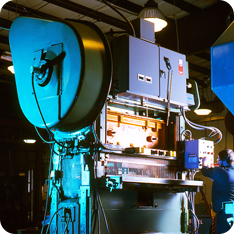

The Smethwick-based manufacturer of metal pressings and welded assemblies has won new contracts to supply seating and HVAC components to the agricultural sector, which have helped the firm achieve 25 per cent annual growth.

The company, which employs 60 staff at its 65,000 square feet facility in Smethwick, supplies over 172,000 pressings every week, ranging from small HVAC nozzles to large heavy-duty side members for coolant systems.

It is now focusing on further expansion and as an increase in capacity means an increase in costs through new machinery and more energy the firm has joined forces with specialist utility management company Control Energy Costs (CEC) to help it manage its energy more efficiently.

Managing director of Baylis Automotive Raj Desai explained that the company brought in external specialists because it does not have the time to monitor usage or look at ways to be more cost effective.

CEC has helped Baylis Automotive to secure a £15,000 refund from the Climate Change Levy (CCL), as well as ongoing savings through a new energy provider, which could work out to as much as £4,000 per month.

CCL is an environmental tax on commercial energy use. It is charged on taxable commodities supplied for lighting, heating and power purposes to business customers in the industrial, commercial, agricultural and public service sectors.

If your business would like advice on ways to save energy or details of schemes to help reduce your bills while lessening your impact on the earth take a look at our Energy saving for businesses page.