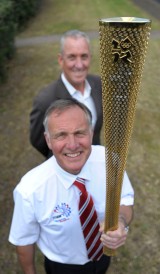

AluCast Ltd in Olympic Torch Deal

Alucast, which employs over 100 people at its Wednesbury base in the West Midlands, has been chosen by Coventry-based Premier Group to manufacture the top and bottom caps for the London 2012 Olympic torch.

The company is responsible for tooling, machining and polishing using gravity casting technology to produce the aluminium components that hold the inner and outer skin of the torch in place. A number of prototypes have already been provided, with full production now underway.

The company is responsible for tooling, machining and polishing using gravity casting technology to produce the aluminium components that hold the inner and outer skin of the torch in place. A number of prototypes have already been provided, with full production now underway.

More than 15 employees are involved in the contract, ranging from design and technical staff to the quality department and experienced casters.

Tony Sartorius, managing director of Alucast, said: “This is fantastic news for everyone involved in our business and underlines our ability to work on complex and demanding projects.”

Mr Sartorius added: “It also shows the manufacturing capabilities we have in the West Midlands and is a great example of the positive impact the Olympics can have on all areas of the UK.”

Designed by East Londoners Edward Barber and Jay Osgerby, the torch is 800mm high and features 8000 perforated circles to represent each one of the inspirational runners on the Olympic Relay planned to mark the opening of London 2012.

The Premier Group, which specialises in turnkey engineering and associated services, beat off international competition to secure the contract to manufacture the torch and has been responsible for setting up a supply chain to deliver the project on time, on budget and to the exacting design and quality standards expected by the London Organising Committee of the Olympic and Paralympic Games (LOCOG).

The Premier Group approached Alucast after it was recommended by a business partner and was immediately impressed with the foundry’s passion for the project, its flexibility in supplying prototypes for testing and its track record in engineering solutions.

Gez Halton, manufacturing director at the Premier Group, explained: “The parts supplied by Alucast are two of the most important components of the torch and we needed to work with a company that understood the design and could deliver the parts to the required finish and importantly, on time.”

Mr Halton added: “After the first meeting, we knew we had found the right partner and the fact they are based locally helps with project management and in ensuring the London 2012 Olympic torch is a truly Great British product.”

The contract follows Alucast’s order to supply complex components to Norton Motorcycles. Investment in a new machining shop has enabled the firm to compete for new orders, it expects to reach nearly £8m of annual sales by the end of the 2012.